Mini Convertible 2.5-way - aha!

Sometimes I think I must be a bit slow. I only thought of this concept today. I had been working on a couple of base options for the mini convertible but I guess neither were compelling enough for me to actually be inspired to build them. So least week I came up with the "mini Convertible S" idea with the sub in the base. But that needs a passive crossover for the mid-tweet.

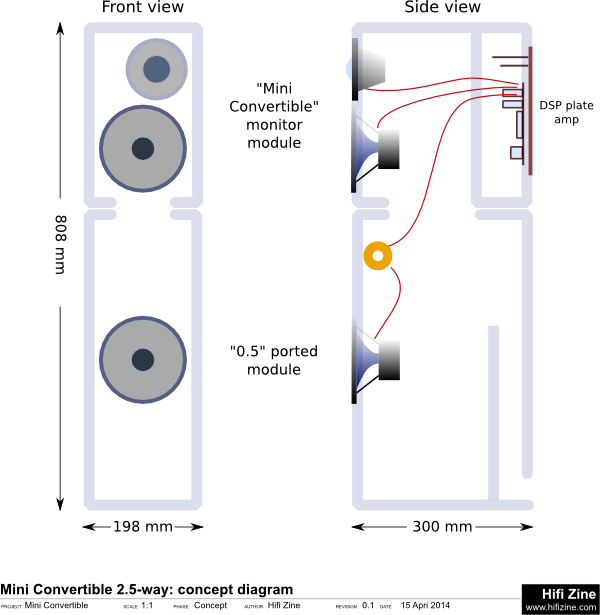

However, the obvious solution, that I finally thought of today, is this:

So: the base module doesn't just add volume, it also adds another woofer. An inductor is needed to lowpass it to make the ".5" part. You don't really get any more output level if run full-range, just a lower f3 (around 45 Hz).

So, I think this is what I might actually build.

Comments

You go girl! :x

You have until October...

Hah, hah, yep! Good idea :-b

Today, I realized something very important. What the speaker I should have designed and made was. It's basically the same, but up a size. The rebellious part of me wants to chuck it all out and start again. The wise part of me wants to stick it through and finish what I said I would do.

October is looming John...

Make a bloody decision fer fark's sake.

I gave up. But at least it was a decision.

Thanks Graham

I'm going to steal that.

I had to write it up anyway to get it out of my head. So this might be the goal for Bathurst 2015: http://johnr.hifizine.com/2014/04/the-convertible-active-loudspeaker-revisited/

2015!?

We meant October 2014!!!

Be careful. We know where you live... X_X

Yes yes, I mean the small one in 2014, the bigger one in 2015

Your time line worse than mine :-O and that's saying something

Yes my friend that is true But I figure if I get one speaker done a year, that's about ten times better than before. And I'm one of those people that has to redesign it and redesign it until it's "right".... [-X

But I figure if I get one speaker done a year, that's about ten times better than before. And I'm one of those people that has to redesign it and redesign it until it's "right".... [-X

So on that note... yesterday I had another breakthrough! Again, completely obvious in retrospect. I was struggling with how to make the box so that the port was easily adjustable in length. Also, I had this problem that in order to bolt the base module to the monitor module you had to stick your arm all the way down it from the bottom, and if you happened to inadvertently get any bracing in the way... too bad sucker.

The simple, obvious solution finally hit me: make the back panel removable, and mount the port on the back panel. I was bogged down in the idea of making a slot port. But that can still be done with this design. So... endless experimentation with different types of port is possible this way. The result is not exactly what you'd call a simple design... but that isn't the purpose of this speaker.

What's remaining now is to figure out the exact height of the module. It's tricky, because it depends on the size of port and on the amount of bracing...!

Ever heard of threaded rod, John?

The other option is to create keyholes ( or 2 dovetail housings...or even t track) in the top of the base to hold the front of the module down and the attach with screws through a longer rear panel.

Yes but... I'm not seeing how that would work though.....

I think thread inserts would work better if your going to be fitting & removing multiple times .

Cheers

Is that also called a T-nut? I have those...

Oh, you mean like these!

http://www.bunnings.com.au/prestige-zinc-plated-type-e-m6-x-30mm-screw-in-insert-nut-4-pack_p4011891

?

Yes , Carbatec or similar suppliers would have a better range ,you could have more luck from the US .

CHEERS

Bigger selection here:

http://www.thewoodworks.com.au/shop/shop-browse/266?vmcchk=1

They're a lot more expensive than T-nuts though...

http://www.carbatec.com.au/veritas-hardware-for-jigs-fixtures_c21019

True...but I didn't want to confuse things further. Fit t nuts to the upper module and bolt through from the lower. Take the back off the lower to access bolt/s.